This month a team from Nordregio ventured East, on another leg of the wood-knowledge-exchange tour of the Baltics and Nordics. Estonia served up piles of wood knowledge on a pallet of well-organised programme points. Come with me as I guide you through the stops and surprises.

Looking at the different growth rings in the wood construction sector, we gained a better understanding of the levels of challenges and opportunities found in each one. From touring spectacular finished buildings, to visiting factories that shoot out houses like they’re made of lego, to inspecting exactly how the wood itself is treated after it’s harvested – we got an exclusive behind-the-scenes look at almost the entire production cycle – from tree logs to towering timber towers.

What was our role in this learning terrain? To explore the pathways and barriers in crafting policies that support and grow this sustainable sector even further.

First stop was the Pelgulinna State Gymnasium – the largest wood building in Estonia. “I’ve never seen a high school like this” was whispered by several people while a teacher enthusiastically explained the school’s unique features. Our eyes feasted on yoga studios, cozy reading nests built into a solid wood wall, real living trees integrated into the floors of the foyer and library. We were also given the opportunity to test out the classrooms for our first presentation round.

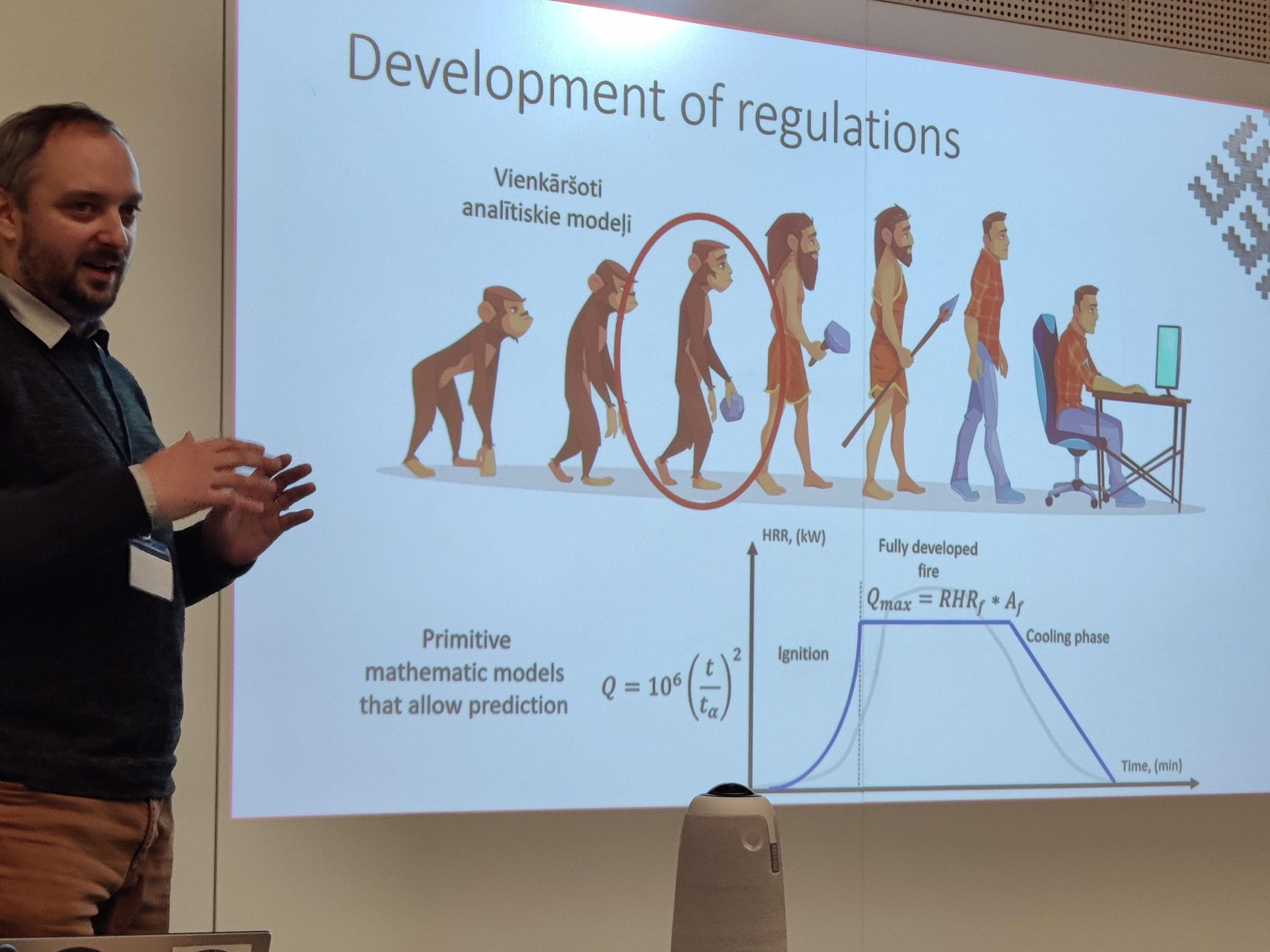

Swedish Jessica Becker from Trästad Sverige, revealed her planning and policy insights in the opening keynote. We then heard Estonian industry insights, particularly about the renovation revolution currently branching its way through Estonia. Old Soviet buildings are in dire need of surface insulation that the wood industry is perfectly adaptable to take on. Lithuanian and Latvian representatives took us into the policy mindset and administrative hurdles of the timber trade. Fire regulations were also presented in a surprisingly whimsical way, comparing human evolution to the regulatory process.

Then came the wood safari. We embarked on a tour of best practices, visiting:

- A prefabrication factory at KMT, where we saw the impressively fast process behind surface renovations. After scanning and designing, the time it takes for two workers to finish a surface wall is two days!

- Saue apartment building – an example of finished renovations – standing between an old Soviet surface and newly renovated one, you would think the entire building was newly built up from the ground. These high-quality improvements prolong the building’s lifetime and provide much-needed insulation for the residents within.

- Timbeco Woodhouse Factory. Entire houses, saunas and kindergartens built like lego and shipped like ordinary amazon packages. A spectacular sight to see – even in freezing temparatures.

- Iglupark was the final stop. A real-life Hobbiton of tiny, yet practical wooden iglus that tourists, locals or businesses can nest in, either for cozy accommodation, hot sauna bliss, or alternative meeting rooms.

Thermory hosted us on the final program day. The largest thermally modified wood producer first gave us a detailed tour of their factory and then opened up their beautiful showroom for us to finish the final part of the program – a policy workshop.

After having filled up on all the finest examples, best practices and presentations, it was time to come together and discuss solutions. And that we did. Our Nordregio team firmly steered the cross-country exchange in a constructive path to policy steps that can bust through the barriers the industry is facing.

Pushing a sustainable alternative through a hardened concrete-and-steel-industry status quo is not easy, but we managed to get the flip-over filled up, with ideas and insights we could take back to work on in Stockholm. Along with some very fancy wood samples from the Willy Wonka wood wonderland that Estonia is.

Stay tuned here, as this team of wood-enthusiasts will carve policy recommendations out of this dense forest of knowledge, in the near future.

The BSR Wood project is funded by The Swedish Institute.